Products Details

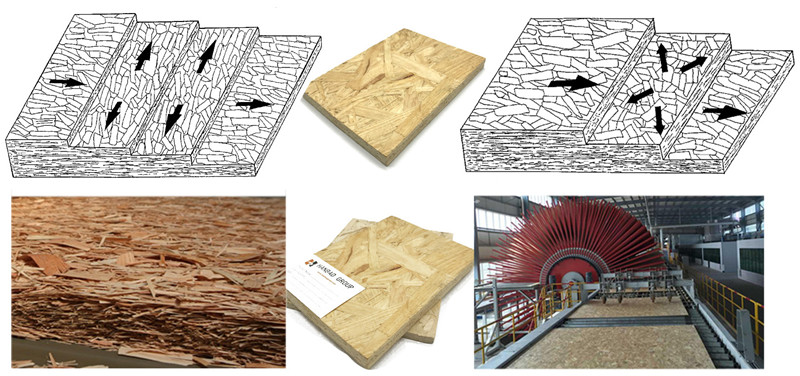

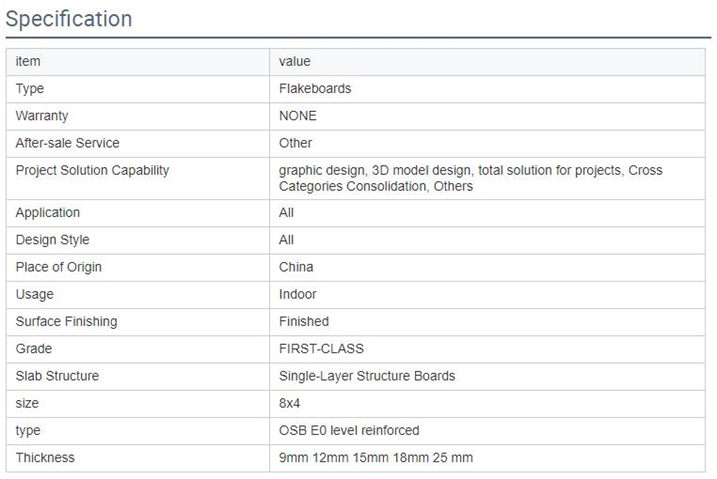

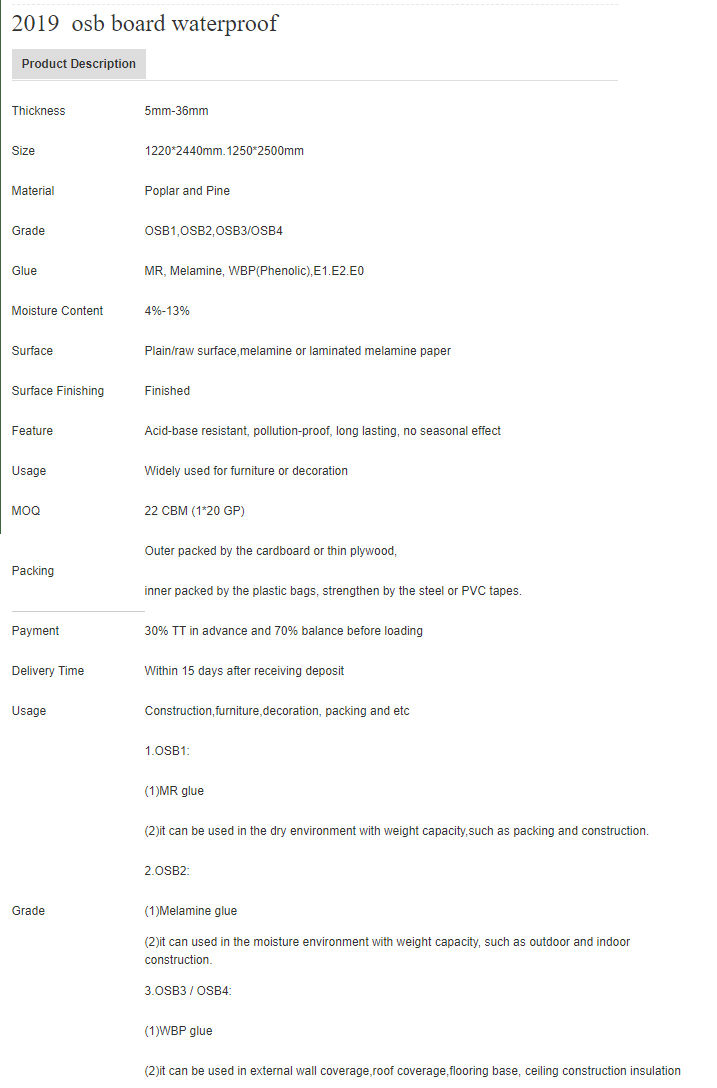

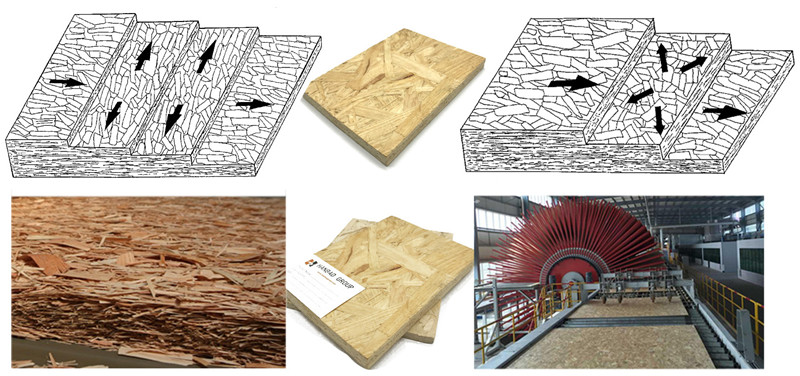

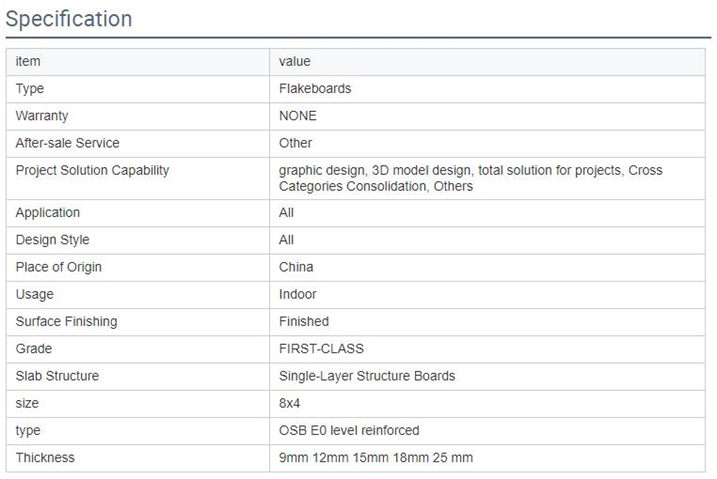

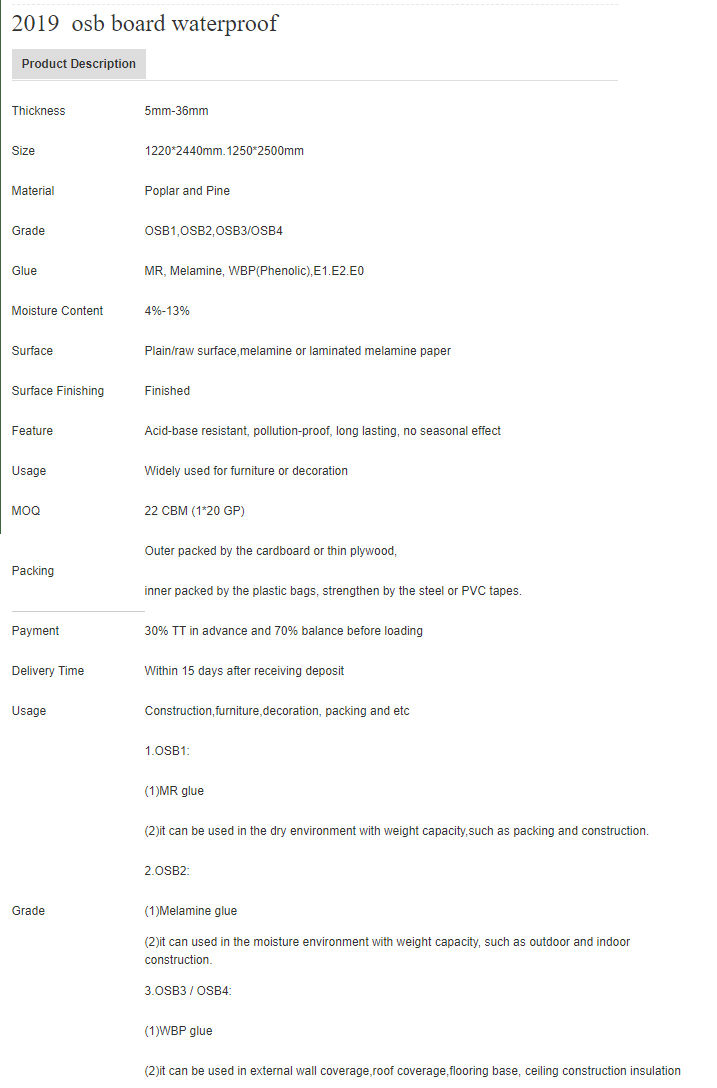

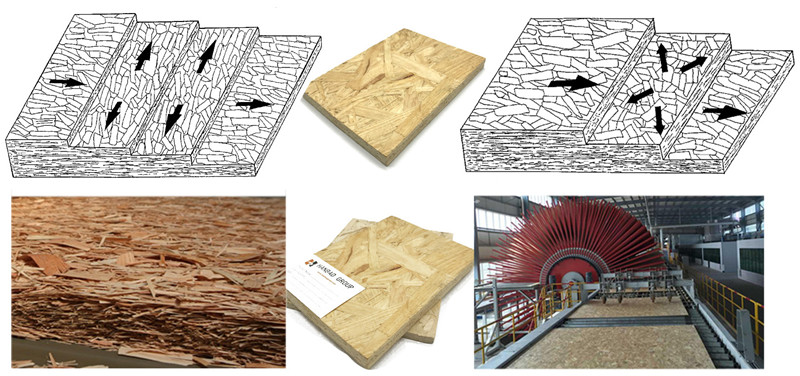

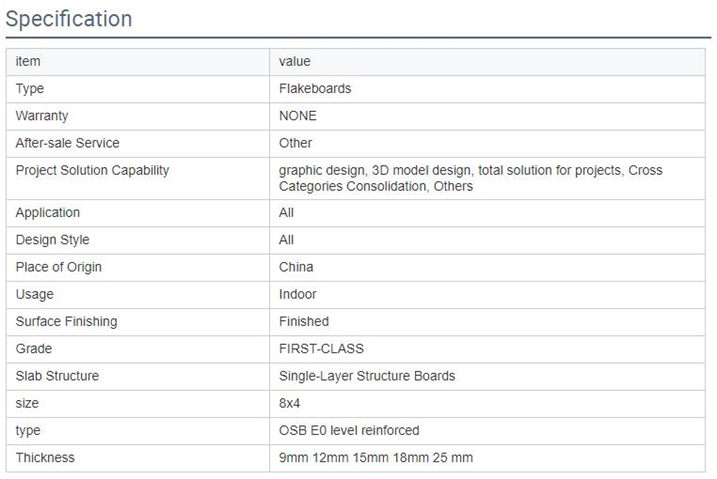

Oriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. OSB is a material with favorable mechanical properties that make it particularly suitable for load-bearing applications in construction. It is now more popular than plywood, commanding 66% of the structural panel market. The most common uses are as sheathing in walls, flooring, and roof decking. For exterior wall applications, panels are available with a radiant-barrier layer laminated to one side; this eases installation and increases energy performance of the building envelope. Phenol-formaldehyde products are considered to be relatively hazard-free. The newer types of OSB use isocyanate resins that do not contain formaldehyde and are considered nonvolatile when cured. Industry trade groups assert that formaldehyde emissions from North American OSB are "negligible or nonexistent". OSB board Advantages 1) Tight construction and high strength 2) Minimum twisting, decontamination or warping 3) No rotten or decay, strong against corrosion and fire 4) Water proof, consistent when exposed in the natural or wet environment 5) Low formaldehyde emission 6) Good nailing strength, easy to be sawn, nailed, drilled, grooved, planed, filed or polished 7) Good heat and sound resistant, easy to be coated Oriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. OSB is a material with favorable mechanical properties that make it particularly suitable for load-bearing applications in construction. It is now more popular than plywood, commanding 66% of the structural panel market. The most common uses are as sheathing in walls, flooring, and roof decking. For exterior wall applications, panels are available with a radiant-barrier layer laminated to one side; this eases installation and increases energy performance of the building envelope. Phenol-formaldehyde products are considered to be relatively hazard-free. The newer types of OSB use isocyanate resins that do not contain formaldehyde and are considered nonvolatile when cured. Industry trade groups assert that formaldehyde emissions from North American OSB are "negligible or nonexistent".

Metal Sheet Cnc Cutting,

L Type Iron Parts,

Precision metal fabrication,

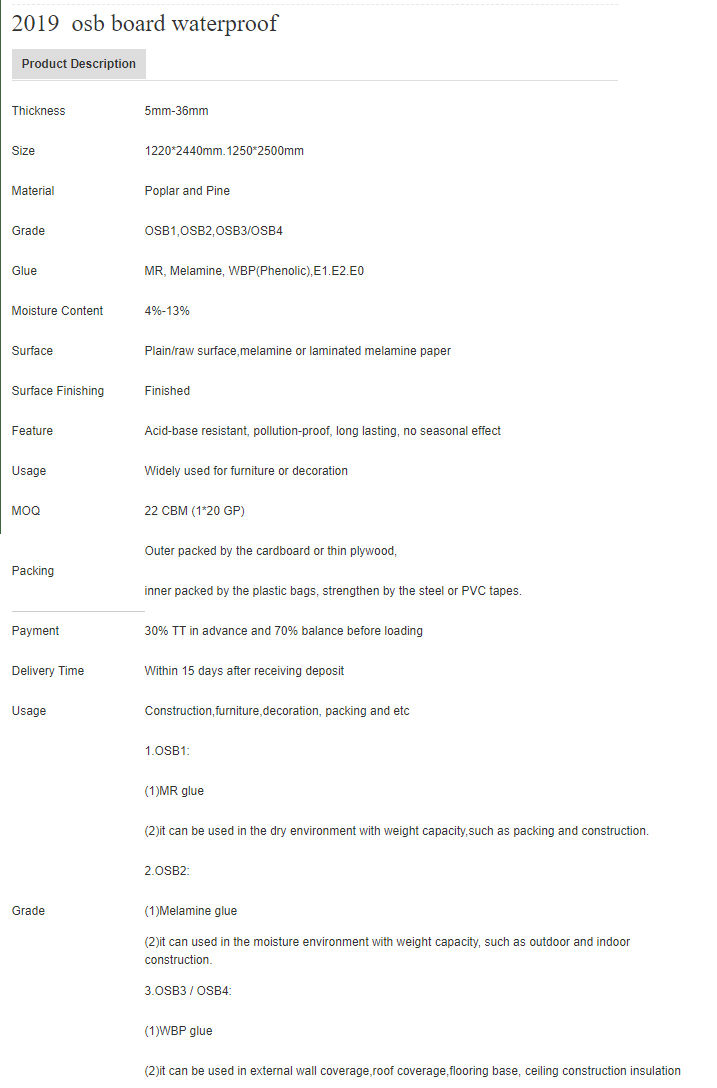

Osb Plywood,

tab shingles,

Black Round Steel Welded Pipe,

Expansion Room,

Nut Screw,

Galvanized coil nails,

China Flat Head Knurled Body Closed End Rivet Nut,